Explore the Function of Gutter Systems in Minimizing the Chance of Rust on Roofs

Gutter systems are an essential component of roofs, serving to collect and channel rainwater to prevent pooling. This is crucial since excessive exposure to rainwater and moisture is a significant factor contributing to the potential of rusting roofs.

These various risks need to be averted to safeguard roofs from rusting. The reason being, corrosion-induced rust can render roofing materials more fragile. If left unaddressed, this situation could lead to subsequent issues such as leaks and damage.

Causes of Potential Rust on Roofs

Roofing materials that are compromised due to rust will be more susceptible to collapsing or giving way, thereby posing a threat to the security and safety of both the residential structure and its occupants. Hence, it’s essential to be aware of various potential factors that can lead to the emergence of rust on roofs:

- Metal Roofing Materials

One of the primary factors that triggers the potential for rusting roofs is the use of metal roofing materials. Metals like iron are particularly susceptible to oxidation and corrosion due to their interaction with the surrounding environment.

This process occurs because metals undergo a chemical reaction with the oxygen in the air and other compounds present around them. Metal elements are more prone to oxidation and transformation into rust when exposed to oxygen and humidity.

Hence, roofing made of materials such as zinc, stainless steel, lightweight steel, multiroof metal, and similar ones will be more prone to rust compared to other materials. To prevent this, metal roofs are typically coated with rust-resistant layers.

- Irregular Metal Surface

Besides the type of material, the irregularity of the metal roof’s surface is also a factor contributing to the potential of rusting roofs. This is due to the fact that an uneven or rough surface creates zones where chemical reactions are more prone to occur.

This is particularly the case with the interactions between oxygen, water, and the metal itself. An uneven surface promotes the development of areas with opposing electrical charges that act as anodes (negative poles) and cathodes (positive poles).

As a result, this initiates electrochemical reactions that are responsible for causing corrosion. On the contrary, if the metal roof’s surface is smoother, sleeker, and clean, the occurrence of corrosion reactions becomes less likely because the formation of anode and cathode poles becomes challenging.

- Exposure to Water

Another factor leading to roof rusting is the effect of exposure to water containing both oxygen and hydrogen (H2O). This is why structures situated in regions with significant rainfall are more prone to roof corrosion.

As rainwater lands on the roof’s surface, the water (H2O) combines with airborne carbon (CO2) to create carbonic acid (H2CO3). This acid progressively breaks down the iron components within the metal roof, initiating the development of rust.

- Humidity Levels

The humidity levels in the vicinity of the roof also play a role in the potential formation of rust. High humidity in the air causes metals to oxidize more readily, as it accelerates the chemical reaction between oxygen and the metal.

Elevated humidity on the metal’s surface also triggers electrochemical reactions that lead to corrosion. Consequently, structures located in areas with high humidity, such as tropical regions, are more susceptible to rusting.

- Contact with Acidic Substances

Typically, individuals who use metal or metal-based roofs apply protective coatings against rust. Nevertheless, the contact with acidic substances like acid rain or specific acidic components in cleaning fluids can gradually deteriorate and undermine these rust-repelling layers.

Once these protective coatings start to peel or suffer damage, the underlying metal becomes more susceptible to the effects of oxygen and airborne moisture, thus initiating the development of rust.

- Scratched Roofing Material

Physical damage on the roof’s surface, such as being scratched by hard objects, can also wear away the existing anti-corrosion coating. As a result, this will trigger an oxidation reaction that accelerates the formation of rust.

Usually, these scratches can appear due to lack of caution while cleaning the roof’s surface using specific tools. Furthermore, contaminants like sand, branches, and others can also cause scratches that initiate corrosion.

Role of Gutter System in Mitigating Roof Corrosion Potential

From the discussion above, it can be understood that exposure to rainwater is one of the main causes of rust formation on roofs. Therefore, it is important to reduce rainwater pooling on the roof to prevent it from reacting with the metal materials present.

One of the solutions is the use of a gutter system. A gutter system is a roof component in the form of pipes that serve as channels for the flow of rainwater that falls onto the roof. Here is its comprehensive function:

- Redirecting the Flow of Rainwater

Gutter systems are specifically designed to gather and channel rainwater from the roof to the drainage system or disposal channels. As a result, water won’t pool for extended periods on the roof’s surface.

- Preventing the Formation of Puddles

Pooled water that forms on the roof is one of the potential of rusting roofs. By using gutters, puddled water can be eliminated or directed to other channels, reducing the potential occurrence of corrosion reactions.

- Preventing Excessive Moisture

Trapped moisture between roofing materials can also trigger rust and corrosion on metal surfaces. By diverting rainwater away from such areas, excessive moisture on the roof can be minimized.

Solutions to Prevent Roof Corrosion

Aside from using gutter systems, there are actually various alternative solutions to prevent rust on building roofs. One of these solutions involves using non-metal roofing materials, as metal is the element most susceptible to corrosion reactions.

An example of a non-metal roofing option is the fiber cement roof by Djabesmen. As its name suggests, this type of roof is crafted from specialized fiber and cement materials combined with other substances, then molded into roofing shapes.

Since it’s not made of metal, the Djabesmen fiber cement roof is guaranteed not to corrode even when frequently exposed to rainwater and atmospheric moisture. Additionally, this material is renowned for being lightweight, resilient to extreme weather conditions, and having a long lifespan.

Its form also carries aesthetic appeal, adaptable to the design of your building or home. As options, the Djabesmen fiber cement roof comes in four variants as follows:

- Djabes 6: Comprising 6 large corrugations with a distance of 180 mm between corrugations and dimensions of 1020 x 250 x 5 mm.

- Djabes 11: Consisting of 11 small corrugations with a distance of 75 mm between corrugations and dimensions of 780 x 150 x 3.30 mm.

- Djabes 14: Featuring 14 small corrugations with a distance of 75 mm between corrugations and dimensions of 1050 x 150 x 4 mm.

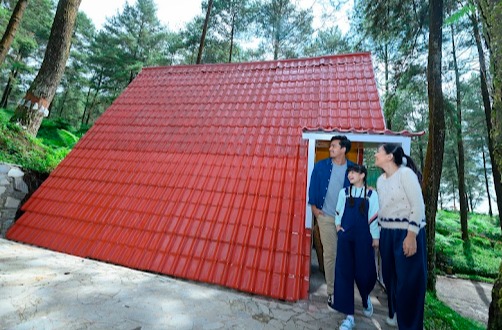

- Djabes Roof Tile: Resembling traditional clay tiles, consisting of 18 leaves per sheet with dimensions of 1150 x 250 x 4 mm

The assortment of roof options discussed can be customized to suit your building’s needs. Thus, to reduce the potential of rusting roofs, Djabesmen presents the optimal solution as a provider of top-notch fiber cement roofing that adheres to the Indonesian National Standard (SNI).

Djabesmen Regains Top Brand No.1 Award for the Tenth Time

Djabesmen Won Top Brand Award

Read Post arrow_right_alt

Tips for Creating a Rooftop Garden

Planning to create a rooftop garden? Discover these valuable tips to elevate its charm and allure!

Read Post arrow_right_alt

Roof Repair Solutions for Urgent Situations

Here are some tips and emergency roof repair techniques that you can implement in critical conditions.

Read Post arrow_right_alt

Here are the Reasons Why Roofs Are Made with Corrugations

Why are roofs made with corrugations? Learn about its rationale and various benefits!

Read Post arrow_right_alt